Industrial X‑Ray Inspection Machine

Manufacturer in China

Advanced Scanning Solutions for

Footwear, Textiles, Apparel & Knitting

1. Why Industrial X‑Ray Inspection Is a Game-Changer

In the high-speed, high-stakes world of mass production—especially in footwear, textile, knitting, and apparel industries—the slightest defect can ripple into financial losses, compliance failures, and reputation damage.

- Broken needles, metal fragments, or foreign objects can cause product recalls, customer injuries, or damage to machinery.

- Manual inspection is slow, subjective, and prone to human error.

- Market demands for non-destructive testing, export compliance, and production efficiency are at an all-time high.

Enter industrial X‑ray inspection machines—non-invasive, automated, and laser-focused on internal defect detection. As a certified Chinese manufacturer with decades of industrial imaging expertise, we offer turnkey X‑ray scanners designed to safeguard product integrity while boosting throughput.

2. Who We Are: Trusted OEM Manufacturer from China

We are one of China’s professional X‑ray inspection system manufacturers—supplying scanning solutions globally to textile mills, apparel factories, footwear producers, and knitting plants.

- Based in Guangdong/Shenzhen, we combine ISO/CE-certified design with user-friendly interfaces and multilingual support.

- Our product line includes conveyorized models (SA4233, SA5030 SA6550) with large tunnels, image logging, and customizable belts.

- We support factory integration: conveyors, label printers, software upgrades, OEM branding, and on-site commissioning.

3. Which industries need to install our x-ray inspection system?

3.1 Footwear Manufacturers

Pain Points:

- Embedded metal nails, staples, or broken needle fragments in soles/padding can injure end users.

- Metal in finished shoes can halt machinery during quality inspections downstream.

- Export compliance requires internal inspection beyond surface-level scanners.

Our Solution:

- High‑penetration X‑ray (80 kV+) scans entire shoe volume.

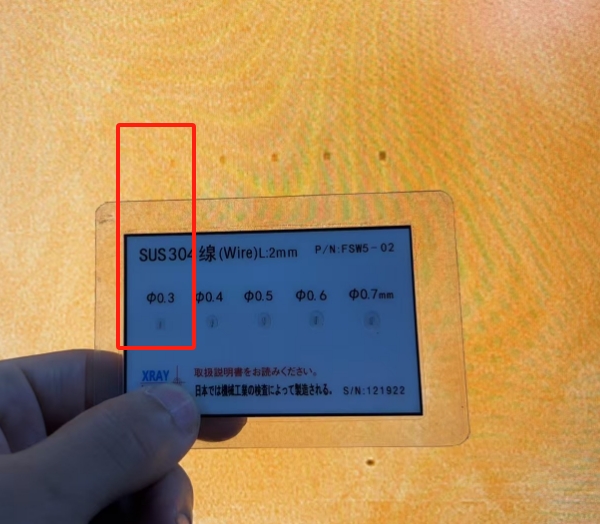

- 0.3 mm metal detection accuracy via SA‑5030.

- Output includes pseudo‑color and grayscale imaging, auto‑zoom, and image memory

- Conveyor throughput of 12–24 m/min minimizes bottlenecks

- CE‑ and ISO‑certified for export approval and consumer safety.

Keywords:

X‑ray shoe scanner, footwear metal detection, broken needle detector for shoes,

shoe quality control X‑ray machine, internal shoe scan.

3.2 Textile & Knitting Mills

Pain Points:

- Broken loom needles can mimic chemical fibers or dye contaminants, leading to high customer return rates.

- Missed fragments reduce compliance with ISO and CE regulations.

- Traditional metal detectors struggle with dense knitted fabrics.

Our Solution:

- Conveyorized needle detectors for fabric rolls up to 600 mm+ wide

- Precision detection of fragments down to 0.3–0.5 mm .

- Embedded Win7 systems with real-time zoom, data traceability, and multi-level access controls

Keywords:

textile X‑ray inspection, fabric needle detector machine, knitting broken

needle scanner, mill foreign metal detection, automated X‑ray textile QC.

3.3 Apparel & Garment Manufacturers

Pain Points:

- Needles, pins, metallic trims (zippers, buttons) create false alarms or exit detection systems.

- Children’s wear demands rigorous metal detection to avoid recalls.

- Manual QC is slow and inconsistent.

Our Solution:

- High-sensitivity X‑ray software filter distinguishes between large metal trims (zippers/buttons) and hazardous fragments

- Precision alerts for metal ≥ 0.3 mm; HD imaging aids differentiation

- Auto-log, admin access levels, and audit-ready traceability.

- Compact conveyor scanners for single-item garment lines.

Keywords:

apparel X‑ray inspection system, garment broken needle detector, clothing metal

contamination scan, children’s wear safety scanner, non-destructive garment QC

X‑ray.

3.4 Children’s Wear & Uniform Producers

Pain

Points:

High risk of injury due to small metal fragments in children's clothing; must

follow export regulations (EU/US/Japan).

Our

Solution:

Low-dose (<0.4 μSv/h) safety-compliant

tunnels; image logging and traceability for mass production; conveyor capacity

0.2 m/s

Keywords:

children’s apparel X‑ray QC, export garment needle detector, EU metal detection

compliance clothing.

3.5 Accessory & Bag Makers

Pain Points:

- Inserts (metal tags, zippers, decorative studs) hide internal metal—risk of broken needle confusion.

Our

Solution:

HD scanning image highlights organic vs inorganic items; advanced filtering

reduces false positives

Keywords:

bag X‑ray metal scanner, accessory inspection X‑ray, handbag needle detector.

4. Why Traditional Detection Methods Fall Short Many factories still rely on manual inspection or low-sensitivity metal detectors to catch defects. These methods often:

- Miss deeply embedded metal fragments

- Struggle with complex or layered materials like shoes and knitted fabrics

- Require significant time and labor, increasing operational costs

Introducing Our Advanced X-Ray Inspection Machines As a trusted Chinese manufacturer with years of expertise, we have developed high-performance X-ray inspection systems tailored specifically for the needs of the footwear, textile, and garment sectors.

Key Applications:

- Footwear: Detect broken needles, nails, and hidden metallic defects in soles and linings.

- Textiles: Identify metallic fragments within fabric rolls, woven and knitted goods.

- Garments: Pinpoint broken sewing needles or contamination in finished clothing, especially children's wear.

- Knitting: Inline detection to prevent damage to machines and ensure safe, clean output.

Top Benefits:

- High-sensitivity scanning (0.3 mm or greater)

- Conveyor belt models for fast and automated QC

- Real-time, color imaging with alarm systems

- CE/ISO certification for international compliance

- IoT and software integration for traceability and audits

Solving Industry Pain Points Our machines directly address common industry challenges:

- Reduce customer returns and production delays

- Ensure compliance with EU, US, and Japanese safety standards

- Save labor costs with automation

- Build brand trust with zero-defect guarantees

Real-World Impact Customers who implemented our SA5030 X-ray systems reported a 90%+ drop in needle-related rejections and a significant boost in export approvals.

If you’re searching for solutions like "X-ray needle detector for textiles," "broken needle inspection machine," or "industrial X-ray scanner for garments," our systems provide exactly what your business needs.

5. Why Choose Us vs. Alternatives

- Deep industry specialization: footwear, textiles, apparel.

- Robust product line: SA4233 SA5030 SA6550.

- Customization expertise: tunnel sizes, belt widths, interfaces.

- Safety & certification: CE, ISO, FDA-ready radiation levels.

- Support & warranty: 24‑month parts, lifetime remote updates.

In today’s competitive global marketplace, ensuring product safety, export

compliance, and brand trust is non-negotiable. Our industrial X‑ray inspection

machines—manufactured in China, certified globally, and tailored to your

specific needs—are designed to meet and exceed those expectations.

Contact us today for a personalized quote, live demo, or factory trial of our

scanners. Let’s help you detect broken needles, hidden metal fragments, and

foreign objects—before they damage your brand or your bottom line.

Email: info@securinadetection.com

Phone: +86-159-14162649

Website: www.securinadetection.com